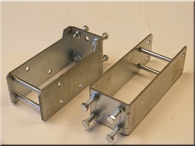

A major supplier of solar power framing approached us to manufacture and assemble this U-clamp. Initially, we used progressive stamping to produce this clamp from 0.187″ thick high strength, low alloy steel. Knurled pins were coined into the U-clamp stamping. Apart from fabricating the U-clamp, we also pierced longer sections, which were used along with the U-clamps to assemble completed fold down frames. By designing and building the dies in-house, we ensured cost effectiveness and met custom specifications. A galvanized material finish was provided to this metal clamp.

Custom Galvanized Steel U-Clamp

Specifications

- Capabilities Applied/Processes

-

Progressive Stamping and Assembly Incorporating Knurled Pin Coined In

- Material Thickness

-

0.187″

- Base Material

-

High Strength Low Alloy Steel (HSLA)

- Material Finish

-

Galvanized

- Secondary Operations Applied

-

Assembly

Knurled Pin Coined into Stamping

- Industry for Use

-

Solar

- Delivery Time

-

6 Weeks

- Delivery Location

-

Throughout USA

- Standards Met

- Product Name

-

U-Clamp

- Project Scope

-

Design and Build Progressive Die, Manufacture and Ship Parts

- Drawing Type Accepted

-

DXF < AutoCAD

- Product Description

-

U-Clamps used in the Manufacturing of Solar Panel Framing

- Product Description/ Background

-

Major supplier of Solar Power framing came to us to manufacture and assemble this metal stamped u-clamp as well as to pierce longer sections and assemble the complete fold down frames